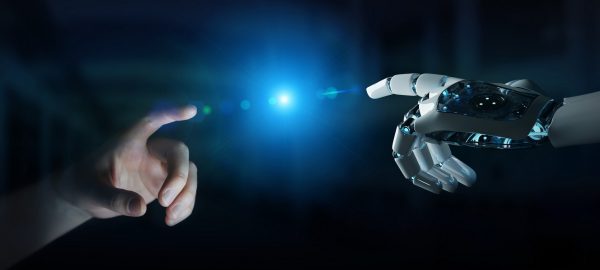

The global transition toward sustainable transportation necessitates the development of high-efficiency powertrains with minimal environmental impact. This study presents a comprehensive comparative assessment of different fuel cell (FC) technologies integrated into a novel Combined Electro-Thermo-Chemical (CETC) cycle. The CETC cycle synergistically combines an internal combustion engine (ICE), a chemical reformer, and a fuel cell stack, utilizing thermochemical recuperation (TCR) to convert engine waste heat into hydrogen-rich reformate.

To address the limitations of previous simplified cycle models, a detailed modular simulation framework was developed using GT-Suite. Three distinct fuel cell types- Solid Oxide Fuel Cell (SOFC), Molten Carbonate Fuel Cell (MCFC), and High-Temperature Proton Exchange Membrane (HT-PEM), were modeled and calibrated against experimental data to capture real electrochemical and thermodynamic characteristics. The performance of each configuration was evaluated through a dynamic case study of a heavy-duty delivery vehicle operating on an urban driving cycle.