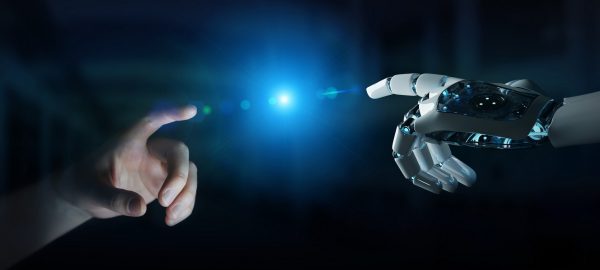

A significant portion of energy losses in global energy consumption is due to friction and wear. Tribology, the science of friction, lubrication, and wear, aims to reduce such losses by developing smarter engineering solutions and design approaches.

Modeling wear processes is challenging because wear behavior strongly depends on material properties, environmental conditions, and other factors. Classic wear models, such as Archard’s (1953), were developed for unlubricated conditions, and even more advanced wear modeling and prediction approaches still lack a complete understanding of the wear processes in the presence of a liquid lubricant film.

In this study we present a new approach to investigate the role of lubricant in wear processes, focusing specifically on solid-liquid wetting properties. A new methodology is utilized to isolate the wetting from other liquid parameters, by modifying the salt concentration in aqueous solutions. This allows us to examine the wetting effect on wear behavior. A new Block-on-Ring tribometer was built, designed specifically for wear tests under lubricated conditions. The experimental setup, capable of measuring both friction force and wear rate, was used to study the tribological performance of various polymers against metal in a controlled aqueous lubrication system.